HVAC Plant Design Services

We offer custom HVAC plant design solutions tailored to your facility’s specific requirements. Whether you’re running a pharmaceutical unit, food manufacturing plant, or cleanroom facility, we ensure high-performance and compliant systems.

🔹 Key HVAC Design Features:

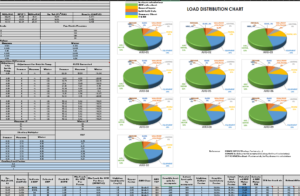

Heat Load Calculation: Accurate thermal load assessments for optimal system capacity.

Equipment Load Analysis: Proper sizing and selection of HVAC units based on plant operation needs.

Environmental Suitability: Designing systems that maintain ideal temperature, humidity, and cleanliness levels.

Cross-Contamination Prevention: Dedicated HVAC zoning to avoid product contamination when handling multiple product lines.

GMP-Compliant HVAC Planning

Our expert team provides comprehensive HVAC planning that balances performance, cost, and regulatory compliance.

🔹 Planning Includes:

Optimized Equipment Placement: Ensuring easy access and future maintenance.

Compliance Audits: Designs aligned with WHO and GMP audit requirements.

Cost Estimation & Optimization: Project cost forecasting with strategies for cost-saving.

Material & Personnel Flow Planning: Ensuring smooth area and material movement within the plant.

Comfort & Usability: Focus on worker comfort and energy efficiency.

Storage Optimization: Planning HVAC systems that consider material storage needs.

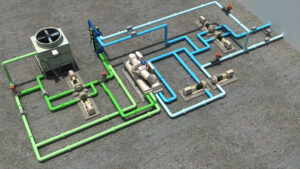

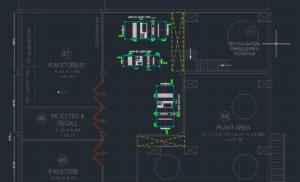

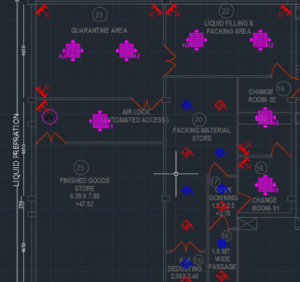

Plant HVAC Layout Services

Our layout services transform your HVAC plans into detailed engineering drawings ready for implementation.

🔹 Layout Deliverables:

Equipment Layout – Strategic positioning for HVAC equipment and components.

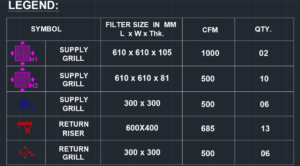

RCP Layout (Reflected Ceiling Plan) – Complete ceiling plan showing diffuser and light placements.

Ducting Layout – Efficient duct routing for optimal air distribution and pressure control.

Pressure Zoning Layout – Pressure cascade maps for cleanrooms and sensitive areas.

Drainage Layout – Drainage plans integrated with HVAC units, especially for AHUs and condensate lines.

Why Choose Us for HVAC Design & Planning?

5+ Years of Experience in HVAC for Regulated Environments

100% Compliance with GMP, WHO, and ISO Standards

High-Efficiency Systems with Low Operating Costs

One-Stop Solution from Design to Layout Execution